Fiberglass Fabric: A Versatile Material For Various Applications

Are you looking for a versatile and durable material to use in various applications? Look no further than fiberglass fabric. In this article, we will explore the numerous uses and benefits of fiberglass fabric, and why it is the go-to material for a wide range of industries. Whether you’re in construction, automotive, aerospace, or any other field, fiberglass fabric has something to offer. Join us as we delve into the world of this versatile material and discover its endless possibilities.

- Introduction to Fiberglass Fabric

to Fiberglass Fabric

Fiberglass fabric is a versatile material that has found its way into a wide range of applications across various industries. This article provides an in-depth introduction to fiberglass fabric, exploring its properties, uses, and benefits.

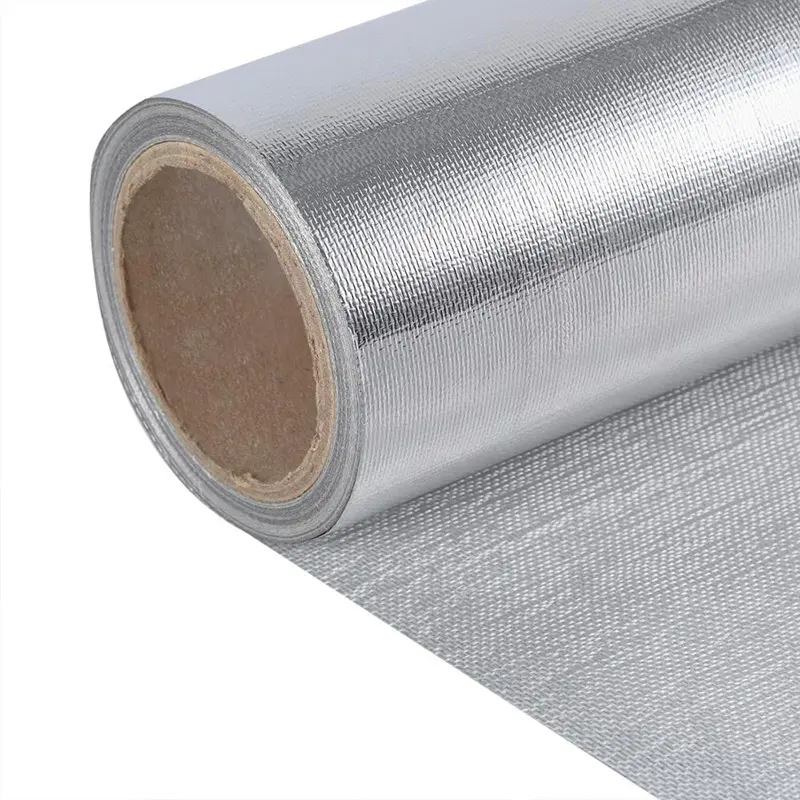

First and foremost, it is essential to understand what fiberglass fabric is. Fiberglass fabric is made from extremely fine fibers of glass that are woven into a flexible and durable fabric. The fibers are typically made from silica sand, which is melted down to form a molten glass. This molten glass is then extruded into fibers and woven into a fabric using a specialized weaving process.

One of the key properties of fiberglass fabric is its exceptional strength and durability. The glass fibers provide the fabric with high tensile strength, making it an ideal material for applications that require a strong and resilient fabric. Additionally, fiberglass fabric is also lightweight, making it easy to handle and transport.

One of the most common applications of fiberglass fabric is in the manufacturing of composite materials. When combined with a resin, fiberglass fabric can create a composite material that is both strong and lightweight. This makes it an ideal material for a wide range of applications, including automotive parts, aerospace components, and sporting goods.

Another important use of fiberglass fabric is in the construction industry. Fiberglass fabric can be used to reinforce concrete structures, providing added strength and durability. It is also used in the production of fiberglass insulation, which is widely used in residential and commercial buildings to improve energy efficiency and reduce heating and cooling costs.

In addition to its strength and durability, fiberglass fabric also offers excellent resistance to chemicals and corrosion. This makes it a popular choice for applications that require a material that can withstand harsh chemical environments, such as chemical processing plants and industrial equipment.

Furthermore, fiberglass fabric is also known for its high temperature resistance. It can withstand high temperatures without losing its structural integrity, making it suitable for use in applications where exposure to heat is a concern.

The versatility of fiberglass fabric also extends to its use in the marine industry. It is commonly used in the construction of boats, yachts, and other marine vessels due to its ability to withstand the harsh conditions of the open sea.

In conclusion, fiberglass fabric is a highly versatile material that offers a wide range of benefits across various industries. Its exceptional strength, durability, chemical resistance, and high temperature resistance make it an ideal choice for a myriad of applications. Whether it is used in composite materials, construction, or marine applications, fiberglass fabric continues to be a popular and indispensable material for a variety of uses.

- Properties and Benefits of Fiberglass Fabric

Fiberglass fabric is a versatile material that has gained widespread popularity due to its properties and benefits in various applications. This article aims to explore the numerous advantages and uses of fiberglass fabric, shedding light on its unique characteristics and why it has become a preferred choice in many industries.

Properties of Fiberglass Fabric:

Fiberglass fabric is a type of glass fabric that is made from strands of glass fibers. These fibers are woven together to create a strong and durable material that is resistant to heat, chemicals, and abrasion. One of the key properties of fiberglass fabric is its high tensile strength, making it ideal for applications where strength and durability are essential. In addition, fiberglass fabric is lightweight and has a high resistance to temperature variations, making it suitable for use in both high and low-temperature environments.

Benefits of Fiberglass Fabric:

The benefits of fiberglass fabric are numerous and diverse. One of the main advantages of this material is its resistance to corrosion and chemicals, making it an excellent choice for use in industries such as construction, aerospace, and automotive. Fiberglass fabric is also non-conductive, making it an ideal material for electrical insulation applications. Furthermore, fiberglass fabric is highly flexible and can be easily molded into different shapes and sizes, making it a versatile option for various manufacturing processes. Additionally, the high tensile strength of fiberglass fabric makes it an ideal material for reinforcing composites and plastics, enhancing their mechanical properties and performance.

Applications of Fiberglass Fabric:

The versatility of fiberglass fabric has led to its widespread use in a variety of industries. In the construction industry, fiberglass fabric is used as a reinforcement material in concrete and other building materials, providing added strength and durability to structures. In the aerospace industry, fiberglass fabric is used to manufacture lightweight and high-strength components for aircraft and spacecraft. Additionally, fiberglass fabric is used in the automotive industry for the production of body panels, bumpers, and other structural components. Other common applications of fiberglass fabric include boat building, wind energy, and sports equipment manufacturing.

In conclusion, fiberglass fabric is a versatile material with a wide range of properties and benefits that make it an ideal choice for many applications. Its high tensile strength, resistance to corrosion and chemicals, and flexibility make it a valuable material in industries such as construction, aerospace, and automotive. With its diverse applications and numerous advantages, fiberglass fabric has become an essential component in modern manufacturing and engineering processes.

Overall, the properties and benefits of fiberglass fabric make it a crucial material for various industries, and its versatility and durability make it an indispensable component in many different applications. With its unique characteristics and numerous advantages, fiberglass fabric has become a go-to material for manufacturers and engineers across the globe.

- Industrial and Commercial Applications of Fiberglass Fabric

Fiberglass fabric is a versatile material that has found its way into a wide range of industrial and commercial applications. From construction to automotive, from aerospace to marine, fiberglass fabric is utilized for its strength, durability, and versatility. This article will discuss the various ways in which fiberglass fabric is used in different industries and how it has become an indispensable material for many applications.

One of the most common industrial applications of fiberglass fabric is in the construction industry. Fiberglass fabric is used in the manufacturing of composite materials that are used to build lightweight but strong structures. It is often used in the construction of bridges, buildings, and other infrastructure projects where strength and durability are crucial. The flexibility of fiberglass fabric also allows for intricate designs and shapes, making it an ideal material for the construction industry.

In the automotive industry, fiberglass fabric is used to create lightweight and strong components for vehicles. From body panels to interior components, fiberglass fabric is used to reduce weight and increase fuel efficiency without sacrificing strength. It is also used in the manufacturing of racing cars and high-performance vehicles where strength and lightweight materials are essential.

Aerospace is another industry where fiberglass fabric is widely used. The material's high strength-to-weight ratio makes it ideal for applications where weight is a critical factor. Fiberglass fabric is used in the construction of aircraft components, such as wings, fuselage, and interior panels. It is also used in the manufacturing of spacecraft and satellites due to its ability to withstand the harsh conditions of outer space.

In the marine industry, fiberglass fabric is used to manufacture boat hulls, decks, and other components. Its resistance to corrosion and ability to withstand the harsh marine environment make it a popular choice for boat builders. Fiberglass fabric is also used in the manufacturing of wind turbine blades, as it can withstand the high wind forces and provide long-term durability.

Apart from these major industries, fiberglass fabric is also used in a variety of commercial applications. It is used in the manufacturing of sports equipment, such as hockey sticks, tennis racket frames, and surfboards due to its strength and flexibility. It is also used in the manufacturing of protective gear, such as helmets and body armor, as it provides a high level of impact resistance.

In conclusion, fiberglass fabric is a versatile material that has found its way into a wide range of industrial and commercial applications. Its strength, durability, and flexibility make it an ideal choice for industries where these qualities are essential. As technology continues to advance, the use of fiberglass fabric is expected to grow even further, making it an indispensable material for various applications.

- Innovative Uses of Fiberglass Fabric in Modern Design

Innovative Uses of Fiberglass Fabric in Modern Design

Fiberglass fabric has long been recognized as a versatile material with a wide range of applications. From industrial use to modern design, fiberglass fabric has found its place in numerous industries. In recent years, the innovative use of fiberglass fabric in modern design has gained attention for its unique properties and potential for creating stunning and durable products.

One of the key qualities of fiberglass fabric is its strength and durability. This makes it an ideal material for applications that require long-term durability, such as in aerospace and automotive industries. The inherent strength of fiberglass fabric also makes it a desirable material for modern design applications, where designers are constantly seeking new and innovative materials to push the boundaries of creativity.

In modern design, fiberglass fabric is being used in architectural elements, furniture, and even wearable art. In architecture, fiberglass fabric is being used to create lightweight and durable structures that push the limits of what is possible in building design. The material's flexibility and ease of manipulation allows architects to create unique shapes and structures that would be impossible with traditional building materials.

In furniture design, fiberglass fabric is being used to create sleek and modern pieces that are not only aesthetically pleasing but also highly functional. The material's versatility allows for the creation of intricate and complex designs that are both lightweight and durable. This has opened up new possibilities for designers to explore new forms and shapes in furniture design.

Another innovative use of fiberglass fabric in modern design is in the creation of wearable art and fashion. Designers are using the material to create striking, futuristic clothing and accessories that push the boundaries of what is possible in fashion design. The material's flexibility and ability to be molded into various shapes and forms allows designers to create one-of-a-kind pieces that are truly unique.

Beyond its strength and durability, fiberglass fabric also offers other benefits that make it a desirable material for modern design. It is lightweight, resistant to corrosion, and has a high strength-to-weight ratio, making it an ideal material for applications where weight is a concern. Additionally, fiberglass fabric is resistant to extreme temperatures and is a great insulator, making it suitable for a wide range of environments and applications.

In conclusion, fiberglass fabric is a versatile material that has found its place in modern design due to its unique properties and potential for creating stunning and durable products. From architectural elements to furniture and wearable art, fiberglass fabric has opened up new possibilities for designers to explore and create innovative designs that push the boundaries of creativity. As technology continues to advance, it is likely that the innovative uses of fiberglass fabric in modern design will continue to evolve, offering even more exciting possibilities for the future.

- The Future of Fiberglass Fabric: Emerging Trends and Developments

Fiberglass fabric has long been recognized as a versatile material that finds uses in a wide range of applications, from construction to aerospace. This article will explore the emerging trends and developments in the fiberglass fabric industry, providing insights into the future of this essential material.

One of the most significant trends in the fiberglass fabric industry is the growing demand for sustainable and eco-friendly materials. As environmental concerns continue to drive innovation in various industries, there is an increasing emphasis on developing fiberglass fabrics that are not only high-performing but also environmentally friendly. Manufacturers are investing in research and development to create fiberglass fabrics that are made from recycled materials or are biodegradable, helping to reduce the environmental impact of these materials.

Another noteworthy trend in the fiberglass fabric industry is the increasing use of advanced technologies in the manufacturing process. Innovations in the production of fiberglass fabrics have led to the development of materials with enhanced strength, durability, and flexibility. Advanced weaving techniques, such as multi-axial and 3D weaving, have allowed for the creation of fiberglass fabrics that are tailored to specific applications, offering improved performance and cost-effectiveness.

Furthermore, the emergence of smart textiles has opened up new possibilities for fiberglass fabrics. By integrating sensors and other technology into fiberglass fabrics, manufacturers are able to create materials that can monitor and respond to their environment. This has significant implications for industries such as healthcare, aerospace, and automotive, where the use of smart textiles can lead to improved safety, performance, and comfort.

In addition to these trends, there has been a growing focus on the development of fiberglass fabrics for emerging industries, such as renewable energy and sustainable infrastructure. The lightweight and high-strength properties of fiberglass fabrics make them ideal for applications in wind energy, where they are used in the construction of turbine blades. Similarly, the use of fiberglass fabrics in the construction of sustainable buildings and infrastructure is on the rise, as these materials offer excellent thermal and acoustic insulation properties, as well as resistance to corrosion and fire.

Looking ahead, the future of fiberglass fabric is likely to be shaped by continued innovation and advancements in materials science and technology. As the demand for sustainable and high-performance materials continues to grow, the fiberglass fabric industry is poised to play a crucial role in meeting these needs. By embracing emerging trends and developments, manufacturers can position fiberglass fabrics as a key material for the future, with applications that span across a wide range of industries.

Conclusion

In conclusion, fiberglass fabric proves to be a highly versatile material with a wide range of applications. Its durability, strength, and resistance to various elements make it an ideal choice for industries such as construction, automotive, aerospace, and even fashion. Its flexibility and ability to be molded into various shapes and forms further add to its appeal. As technology continues to advance, we can expect to see even more innovative uses for fiberglass fabric in the future. Whether it's in the form of reinforcement for concrete, insulation for electrical components, or even as a lightweight yet durable fabric for clothing, fiberglass fabric is sure to continue making a significant impact in a multitude of industries.